We capture value not previously realized through more efficient utilization of woody biomass components

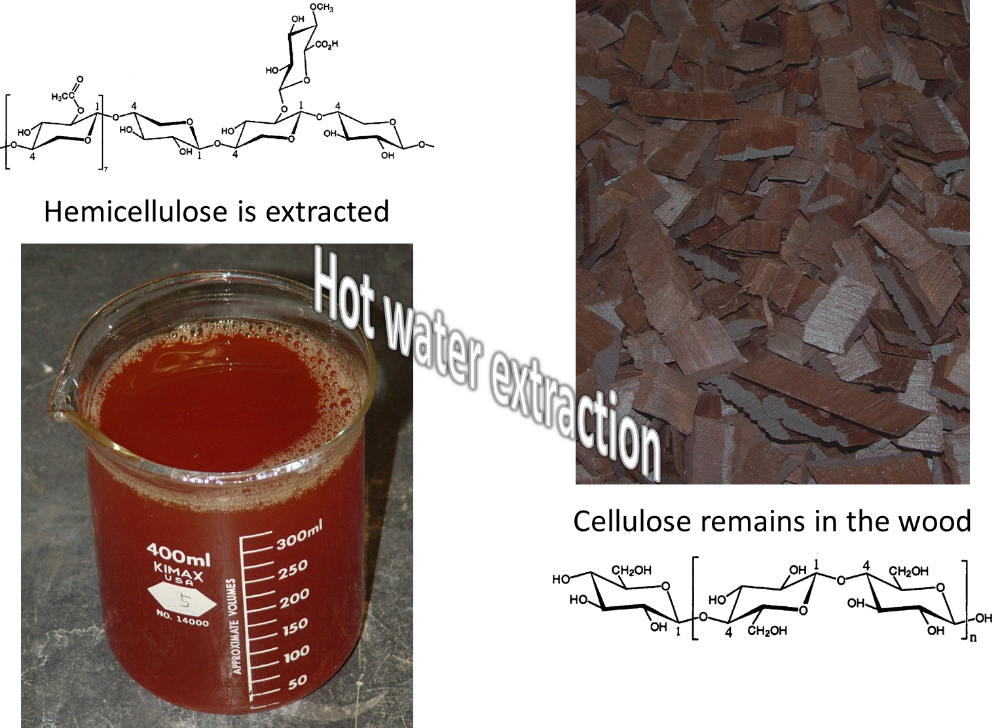

ABS biorefinery technology mimics the natural process of decomposition. By adding non-food biomass and water in a specially-designed pressure cooker, the chemical reactions that would happen over the course of many years in nature occurs instead in a matter of hours. Nearly 25% of the dry biomass is broken down into different types of industrial chemicals and sugars that can be fermented to direct replacements for petroleum products, such as liquid biofuels and biodegradable plastics. The residual, hot water extracted biomass (still in fibrous form following the cooking process), is meanwhile improved for subsequent manufacture of pulp and paper, fiberboard, fuel pellets, or other new-technology derivatives of cellulose and lignin.

The benefits of ABS process technologies are threefold. First, we use inexpensive feedstock that is not sensitive to price shock. This includes low-quality, native-forest wood, biomass crops, and agriculture residuals. Second, our process is simple, cheap, and clean. We have smaller operational costs than comparable technologies because of low energy and chemical consumption per dollar of revenue generated. Lastly, we produce an increased or improved variety of products from the same wood supply. Developing the infrastructure to manufacture any single product using a biomass feedstock is expensive and difficult to generate a positive return on investment. By manufacturing fermentation feedstock (sugars) as well as a number of different renewable chemicals from non-food, plant biomass, our biorefinery concept can generate significantly larger, sustainable profits than a single product line chemical plant or standalone pellet mill.

Have a look at our process in the image gallery below.